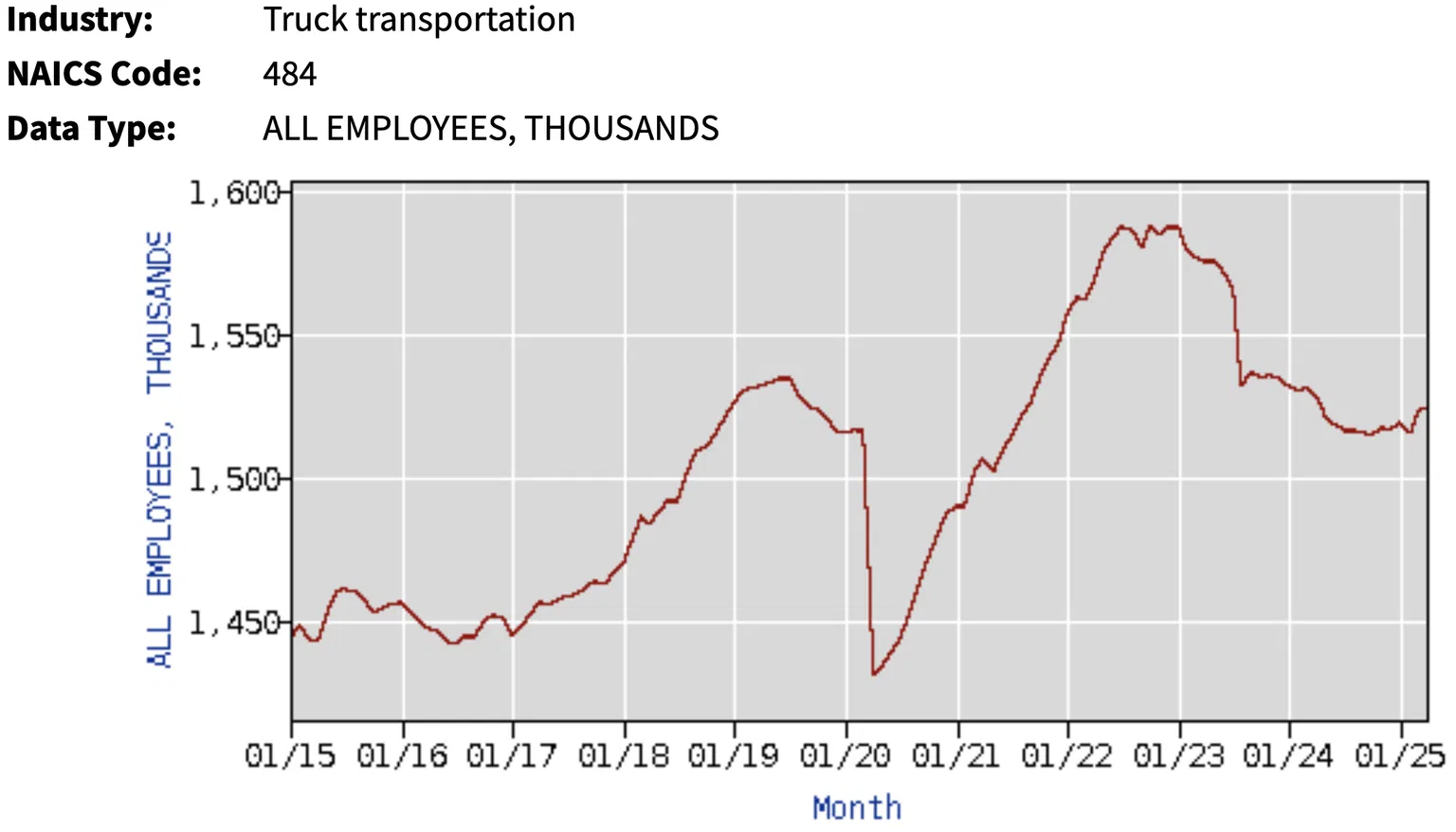

In April 2025, the U.S. transportation labor market sent mixed signals. According to new data from the Bureau of Labor Statistics, trucking employment, which showed strong momentum in March, dramatically slowed in April, adding just 1,400 jobs after a 7,000-job spike the previous month. Meanwhile, warehousing and storage jobs surged by nearly 10,000, fueled by importers rushing to bring goods in ahead of anticipated tariff increases.

This uneven hiring landscape reflects broader supply chain uncertainty and a cautious economy shaped by global trade policy, inventory management strategy, and labor dynamics. For manufacturers and distributors, this environment presents a clear message: flexibility and visibility across your logistics and inventory operations are more critical than ever. That’s where a solution like Frontier ERP becomes an essential tool.

Understanding the Trucking Labor Trends

The transportation and logistics sector as a whole grew by 29,000 jobs in April, but almost all of that growth came from warehousing and storage. Truck transportation’s job growth was anemic, railroad hiring was flat, and courier services posted only modest gains. Analysts attribute the warehouse boom to proactive inventory stocking, as businesses tried to get ahead of the potential cost hikes tied to tariffs.

Source: Freightwaves.com (Chart: Bureau of Labor Statistics)

Truck transportation employment is still 3.2% lower than it was a year ago, and nearly 4% below its July 2022 peak. This suggests that transportation companies are cautious, wary of overextending themselves amid uncertain demand.

In contrast, warehousing has been on a hiring spree, with March and April numbers revised sharply upward. With inventory levels swelling, many organizations needed more space and more people to handle the influx of goods, especially as last-minute freight landed stateside.

Why This Matters for Manufacturers

Whether you’re a furniture maker, window and glass fabricator, or cabinet manufacturer, you are likely feeling the effects of these trends:

-

Truckload shipping delays or shortages can impact your ability to meet delivery commitments.

-

Fluctuating inventory levels can complicate production schedules.

-

Rising labor costs and inconsistent job growth in logistics make it harder to plan.

As David Spencer of Arrive Logistics points out, “proactive safety stocking” helped create short-term transportation demand—but the long-term picture is uncertain. That uncertainty trickles down the supply chain, affecting everyone from raw material suppliers to final mile shippers.

How Frontier ERP Can Help You Stay Agile

Manufacturers facing this complex supply chain climate need real-time visibility, responsive planning tools, and integration across all departments—from procurement and production to warehousing and shipping. Frontier ERP delivers exactly that.

1. Manage Fluctuating Inventory with Smart Forecasting Tools

With proactive inventory buildup now a strategic warehousing necessity, Frontier ERP allows manufacturers to track stock levels in real-time, forecast demand accurately, and plan for multiple scenarios. You’ll know when to increase production or scale back, even when the outside market is volatile.

2. Optimize Truckload Shipping with Dispatch Planning

Frontier ERP includes dispatch and logistics planning tools that help businesses maximize truckload efficiency, respond to shortages, and ensure on-time delivery. Integration with systems like Varsity Logistics and tools like iDispatch and iSchedule provide added control over your shipping strategy, especially valuable in a labor-constrained environment.

While trucking labor numbers decreased in 2025, jobs in warehousing and inventory control have been on the uptick.

3. Streamline Warehousing with Inventory and Distribution Control

As warehousing employment spikes, Frontier ERP helps manufacturers align their warehouse operations with real-time production and sales data. Many manufacturers choose to integrate their warehouse management system (WMS) software with their ERP for optimum performance. Automating picking, packing, and cycle counting from a WMS provider like our partner, Logimax, improves accuracy and reduces labor costs.

4. Adapt Quickly with Integrated Financial and Operational Planning

Tariffs, labor changes, and freight costs all impact your bottom line. Frontier ERP connects your financial management tools to operational data so that you can understand the true cost of goods sold, adapt pricing strategies, and ensure profitability.

5. Improve Labor Allocation with Resource Visibility

When labor availability is uncertain, like in today’s trucking and warehousing sectors, it’s vital to know where your people are most needed. Frontier ERP tracks labor usage and helps managers deploy staff effectively, especially during seasonal surges or supply chain shifts.

Planning for the Rest of 2025

Supply chain instability is becoming a recurring theme, with revised jobs data and unpredictable hiring cycles reflecting an economy at a turning point. For manufacturers, staying responsive to these changes means leveraging technology to create flexibility and resilience.

Frontier ERP offers manufacturers the ability to:

-

See what’s happening in real-time across their supply chain.

-

Adjust to demand and inventory changes without causing production bottlenecks.

-

Communicate efficiently between sales, production, purchasing, logistics, and finance.

Conclusion

The April jobs report is a reminder that manufacturers can no longer rely on stable logistics networks or predictable labor markets. With truck transportation employment stalling and warehousing expanding rapidly, companies must be equipped to pivot. Frontier ERP helps manufacturers of made-to-order and engineer-to-order products stay ahead—offering the tools to forecast more accurately, ship more efficiently, and operate profitably even when external conditions are volatile.

To learn how Frontier can support your manufacturing operation in today’s uncertain environment, contact us for a demo or consultation below, or stop by and see us at AWFS® Fair 2025 in July!