In complex manufacturing, product configurations play a crucial role in streamlining processes from order entry to production and material procurement. They are especially important for manufacturers of kitchen and bath cabinets, doors, windows, and window treatments, to name a few. However, a common drawback is the absence of a real-time connection with 3D product configurations and engineering drawings generated in Autodesk Inventor or other CAD programs.

Incorporating 3D modeling and CAD with Frontier ERP can give your company a significant advantage. Enter Frontier CADFlow—a scalable module that seamlessly bridges the gap between CAD programs and Frontier ERP’s product configuration tools. CADFlow incorporates a comprehensive CPQ (Configure, Price, Quote) feature. The CPQ tool expedites product design and cuts costs, delivering products precisely tailored to meet customer expectations.

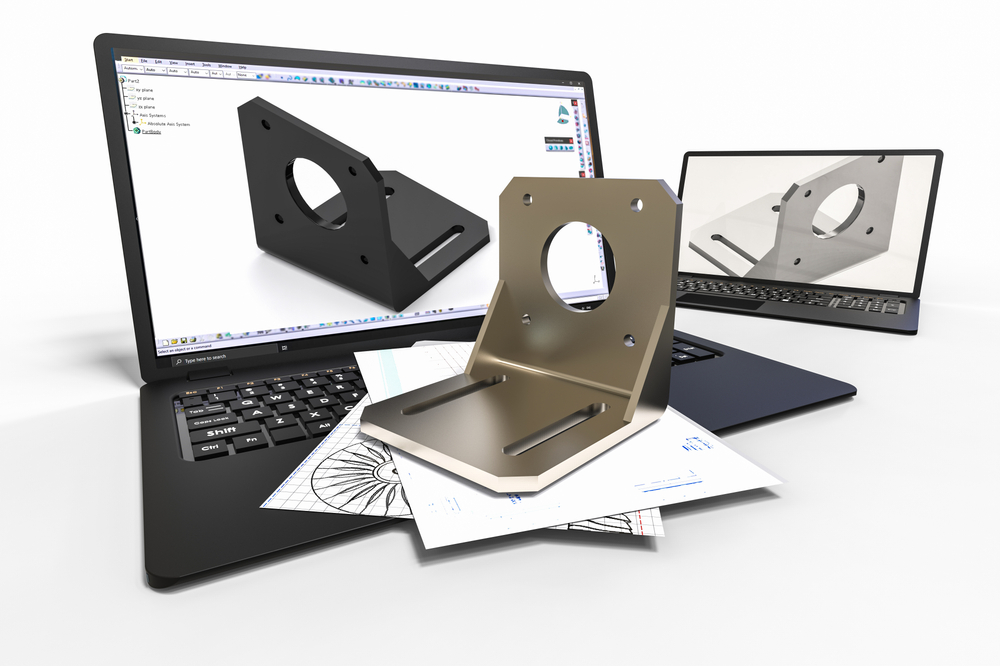

How Does CADFlow Work?

![]()

CADFlow operates by automating the generation of detailed 3D models, drawings, and manufacturing data for each uniquely configured order. Working in harmony with Frontier ERP’s product configurator, this automation not only guarantees precision but also eliminates data redundancies. This ensures a seamless and more efficient manufacturing process. All outputs are produced using both your existing CAD models and the product configuration rules housed in the Frontier ERP CPQ.

Benefits of Choosing CADFlow

- Enhanced Visualization and Communication:

- Power your quote-to-sale process with robust 3D visualization and communication capabilities.

- Accelerate new product development, saving valuable time and resources.

- Cost-Effective 3D Product Configurations:

- Reduce engineering costs associated with custom configurations and time to rebuild models.

- Improve manufacturing performance and enhance product comprehension.

- Leveraging Existing Resources:

- Utilize your existing models, rules, database, and expertise effortlessly.

- Leverage CAD design skills for model development, ensuring a seamless transition.

- Optimize Existing Frontier IT

- Runs on dedicated servers without requiring client workstation modifications.

- Advanced cache management, multi-threaded processing, and selectable processing modes ensure optimal performance, even in high-volume applications.

- Eliminate Integration Issues

- Seamless and secure integration with Frontier ERP and Autodesk Inventor and other CAD programs.

3D Integration with Autodesk Inventor

CADFlow takes full advantage of Autodesk Inventor’s 3D design and visualization capabilities and eliminates integration issues. Frontier recognizes the design rules and constraints defined in an Inventor model. Assemblies defined in Inventor can be used to drive the multi-level work order structure in Frontier. The components defined in each sub-assembly can be used to populate the bill of materials (BOM) for each work order. CADFlow reduces the need to duplicate both product and BOM rules. This synergy results in accelerated product design and delivery, accompanied by cost reductions.

Flexible Implementation Models

Tailor the integration level that suits your business:

1. Frontier-Only Model

The Frontier ERP configuration drives the generation of a configuration-specific Inventor model representing the ordered product. The Inventor model automates the generation of configuration-specific CAD drawings, manufacturing documents, and model images.

2. Inventor-Only Model

Frontier supplies the product configuration order entry options. The Inventor model applies rules, defines material, and returns detailed configuration and material requirements back to Frontier, along with the configuration-specific Inventor model.

3. Combined Model

Makes better use of each application’s strengths. For example, there may be calculated configuration values, such as elliptic arc lengths, that are readily available within Inventor. These calculated attributes can be returned to Frontier, reducing the complexity of Frontier’s rules and reducing redundant information. There is no need to replicate the calculation in Frontier.

Improve Product Comprehension and Communication

During order entry, real-time 3D model renderings aid in product visualization. This is especially helpful when working directly with architects, designers, or end customers during the design process. Visible simply by double-clicking the rendering, the full 3D product configurator model view provides access to each detail, including dimensions, sub-components, and material information. By allowing the customer to visualize their custom order beforehand, it ensures that the final product aligns perfectly with their expectations.

Maximize Your Frontier Investment

CADFlow seamlessly integrates 3D product configuration into your existing workflow:

- No Additional Learning Curve

- No need for additional configurators; leverage your existing knowledge.

- Rapid Deployment

- Utilize your existing models for swift implementation.

- Future-Ready Solution

- Grow with the Frontier ERP confidently, ensuring a sustainable solution.

Make the most of your 3D product configurations and designs with Frontier ERP’s CADflow. To learn more or see a demo, contact us today!